Optimized & deployed across the entire supply chain

Store Replenishment

Solutions

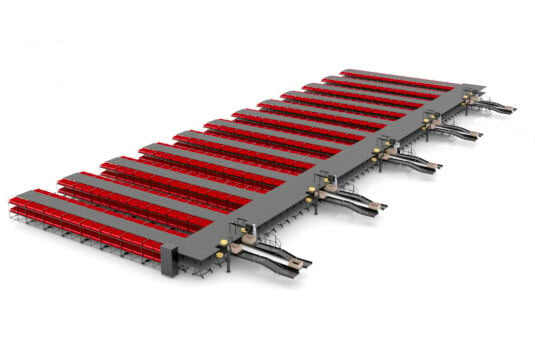

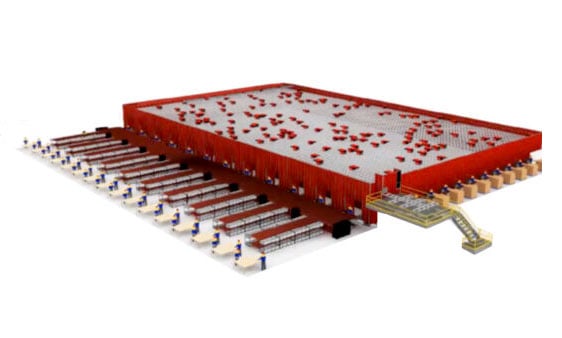

Modern distribution and fulfillment advancements enable retailers to boost throughput and reduce costs and errors in product sortation. The tSort™ robotic sortation system, a key part of Industry 4.0, offers a modular, scalable, and cost-efficient solution for each and innerpack sortation. With a rapid design and deployment cycle, it operates on a robust proprietary Transcend software platform and is backed by a leading global supply chain engineering company.

Modern Distribution and Replenishment with tSort Modular, scalable, and cost-efficient solutions for sortation.

INTELLIGENT ROBOTS, INNOVATIVE SOFTWARE, AND DECADES OF EXPERIENCE

Transforming Store Replenishment with Tompkins Robotics

tSORT E-Commerce Fulfillment

tSort integrated with automated goods-to-person technology

Autostore provided by Dematic Australia

Enhancing Efficiency in Distribution

Optimizing Fulfillment with tSort

Shelf Ready Replenishment

tSort™ can be combined with a wide range of picking solutions, from manual to fully automated goods to persons systems, for larger, more efficient waving and batching.

Cross-dock Sortation

Facilitates sortation of inbound product with an immediate allocation to store directly to the outbound shipping containers.

Reduced Capital Investment

Whether picking via automated goods to person technologies or manually, the batch efficiencies driven by tSort™ results in a lower total fulfillment capital investment.

Flexibility

Flexible, modular, and portable – switch sort plans on the fly, add a robot in seconds, sort destinations in hours, “Lift and Shift” capabilities allows moves to other sites.

Labor Reduction

Reduces labor dramatically – Batch picking with tSort™ consolidation is 50% of traditional store order fulfillment.

Wide Range of Unit Handling

tSort™ offers multiple tray and crossbelt designs, optimized for different products, that can be easily changed, resulting in a broader range of product handling compared to traditional systems.

Tompkins ' Advantage

60%

Less Labor Requirement

4x

Improved Productivity

2,500+

ROBOTS IN A SINGLE SITE

1,000,000

Shipments Per Week

Optimized & deployed across the entire supply chain

Enhancing Efficiency in Distribution

Tompkins Robotics focuses on robotic automation of distribution and fulfillment operations. Beginning over five years ago with our robotic sortation solution, tSort we have continued to develop innovative solutions to provide our customers’ unmatched flexibility and capacity throughout their supply chain processes.

Enhancing Efficiency in Distribution

Experience unparalleled efficiency and precision in store replenishment and distribution with Tompkins Robotics solutions. Our innovative products, including tSort, PickPal, and Transcend, are designed to streamline every aspect of the replenishment and distribution process.

tSort's autonomous navigation and adaptive routing capabilities ensure swift and accurate sorting of items, facilitating seamless replenishment of store shelves.

PickPal's advanced vision systems enhance picking processes, minimizing errors and maximizing order accuracy.

With Transcend, our comprehensive workflow and sort orchestration platform, you can configure tSort to ensure your unique supply chain requirements are baked into your store sortation workflows.

Trusted by our customers across the globe