Optimized & Deployed Across The Entire Supply Chain

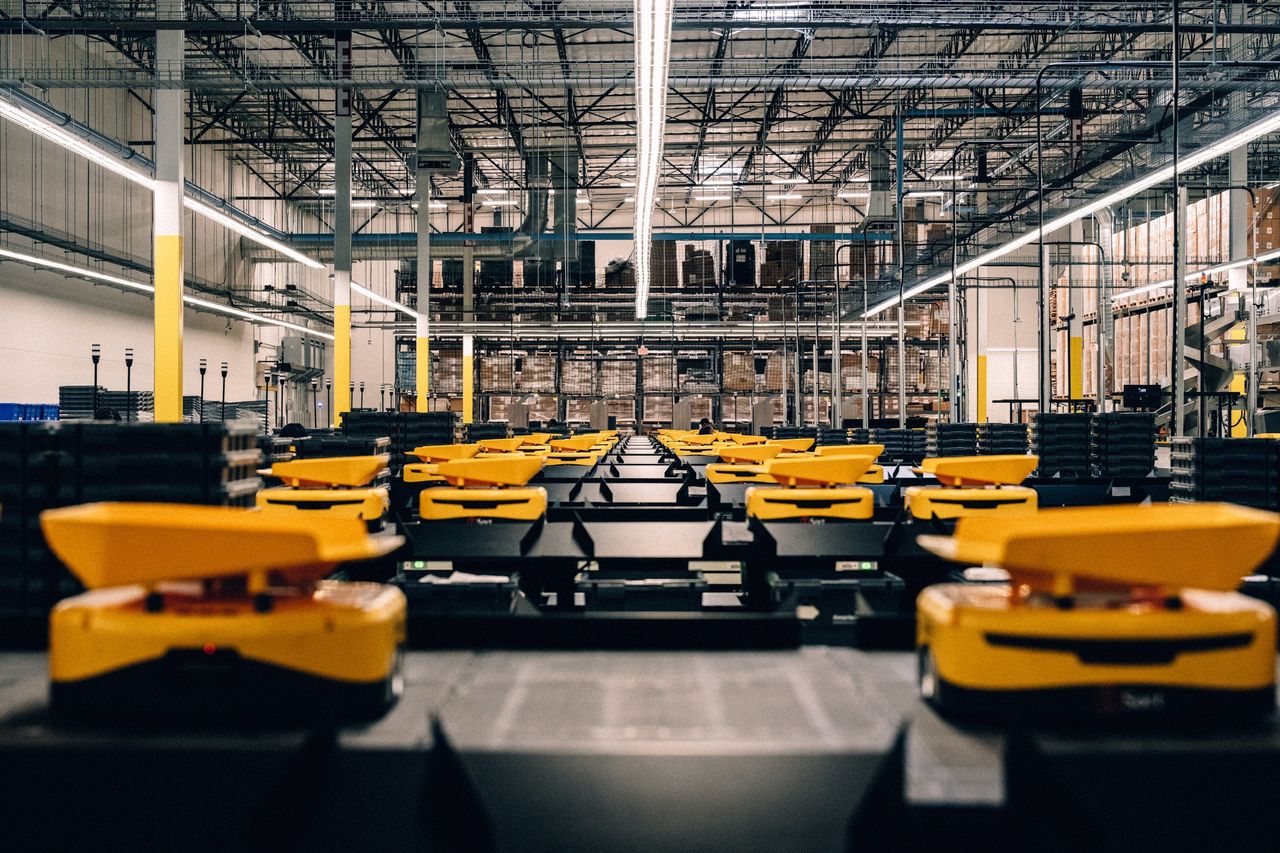

Goods-to-Person Integration

Tompkins Robotics’ Goods-to-Person Integration automates tote handling, increasing storage density and enhanced flow in fulfillment operations, significantly boosting efficiency in picking, storing, and item delivery.

Enhance efficiency and reduce costs with high-density and throughput solutions from Tompkins Robotics.

Intelligent robots, innovative software, and decades of experience

Transforming Goods-to-Person with Tompkins Robotics

PickPal

PickPal allows for multiple PickAssist solutions in growing fulfillment operations.

Integrations

Seamlessly integrate robotics and warehouse systems with stable and flexible tech.

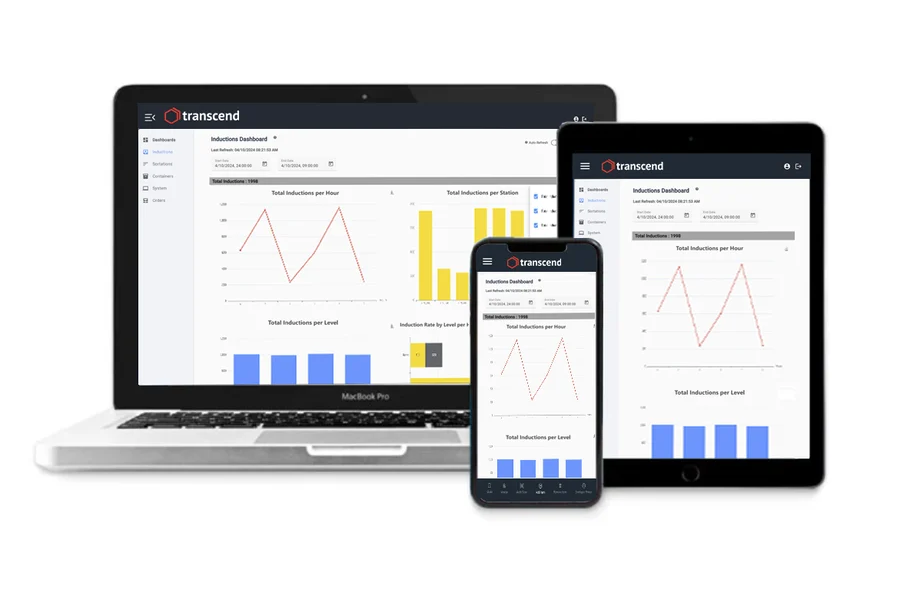

Transcend

Software platform that orchestrates order flow and execution enabling the automated environments of tomorrow’s supply chain.

xChange

xChange has multiple options to move orders between robotics systems or process areas.

tSort3D

With tSort3D, operations can increase sort density in the same floor space, increasing throughout and ROI effectiveness.

Tompkins ' Advantage

60%

Less Labor Requirement

4x

Improved Productivity

2,500+

ROBOTS IN A SINGLE SITE

1,000,000

Shipments Per Week

From startups to global giants

Revolutionizing Order Fulfillment Efficiency

High Flow Rates

Pair multiple ground robots to archive up to 600 inbounds and 600 outbounds of totes

Quick Deployment & High Stability

The system can be deployed within a month, requires minimal maintenance, and allows for remote software adjustments. Additionally, its components are fully modular and easily replaceable.

High Storage Capacity

The system features bidirectional picking, suitable for racks positioned both in front and behind. It operates efficiently in aisles as narrow as 850mm. With a minimal 10mm space between totes, a single robot can handle up to 150 totes per hour, adept at both picking and storing tasks.

High Flexibility

This system is adaptable to a wide range of totes and racks. Multiple robots can operate in a single aisle, and the entire setup can be effortlessly scaled up by incorporating additional racks.

Unrestricted by Rack Types and Site Conditions

The current racks and totes can be employed to minimize costs. The infrastructure needs are modest, and there's no need for specialized floor treatments.

High ROI

The man-to-tote route optimizes labor costs for picking operations. High-density storage enhances space utilization, leading to reduced expenses related to space.

Trusted by our customers across the globe