Optimized & deployed across the entire supply chain

Micro Fulfillment Solutions

Tompkins Robotics’ tSort™ solution offers rapid, cost-effective micro-fulfillment options in existing spaces creating a unique ASRS option with faster deployment times and lower construction costs transforming vacated retail spaces into efficient, right-sized fulfillment centers.

Tour the Tompkins Robotics Lab

We offer in-person and virtual tours of our cutting-edge robotics facility.

Intelligent robots, innovative software, and decades of experience

Transforming Micro Fulfillment with Tompkins Robotics

tSort

tSort™ is versatile and requires reduced infrastructure spend to implement, making it the best sorting option for limited footprint and building options.

PickPal

PickPal compliments micro fulfillment solutions with its multiple PickAssist options and formats.

Integrations

Seamlessly integrate robotics and warehouse systems with stable and flexible tech.

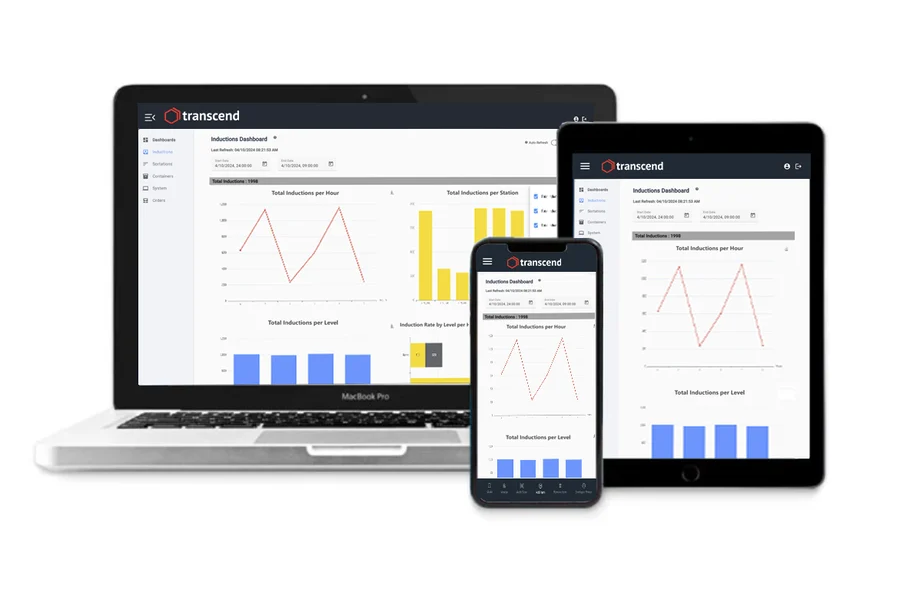

Transcend

Transcend drives our orchestration workflows to allow unique fulfillment workflows to stay efficient and meet committed SLAs.

xChange

Our xChange product line has multiple options to move orders between robotics systems and process areas.

tSort3D

With tSort3D, operations can increase sort density in the same floor space, increasing throughout and ROI effectiveness.

Tompkins ' Advantage

60%

Less Labor Requirement

4x

Improved Productivity

2,500+

ROBOTS IN A SINGLE SITE

1,000,000

Shipments Per Week

STREAMLINING MICRO-FULFILLMENT WITH TSORT

Revolutionizing Micro Fulfillment Efficiency

Inbound Sortation

Facilitates inbound sortation of mixed containers of items and small cases to aisle segments, for more efficient shelf stocking.

Buy Online Pickup In-Store (BOPIS)

Enhances BOPIS order processing by allowing store batch picking by department or aisle. Automated, accurate and efficient order consolidation.

Extensive Range of Software and Hardware Options

Facilitates home delivery orders in the same manner to allow fast processing and minimize labor and store aisle congestion. BOPIS & e-commerce picked and sorted in the same batch, on-demand.

Automates Order Consolidation

Automates order consolidation with accuracy virtually at 100%, increasing customer service and satisfaction.

Labor Reduction

Reduces labor dramatically – Batch picking with tSort™ consolidation is 50% of traditional store order fulfillment.

Home Delivery Sortation

Sorts outbound home delivery packages by route or local hub destination for DDU, local carriers and other delivery methods allowing same day / next-day delivery at a pre-sort final mile introduction cost.

Grocery and Superstore

Processes room temperature, refrigerated, frozen, fresh and various product types (eggs, produce, cases of water – 98% of a grocery store or supercenter).

Flexibility

Flexible, modular and portable – add a robot in seconds, sort destinations in hours, move to another site overnight.

Cost Savings

More cost-effective single store solution than ASRS. Typically 1/10th cost, 1/10th space and 67% labor reduction.

Trusted by our customers across the globe